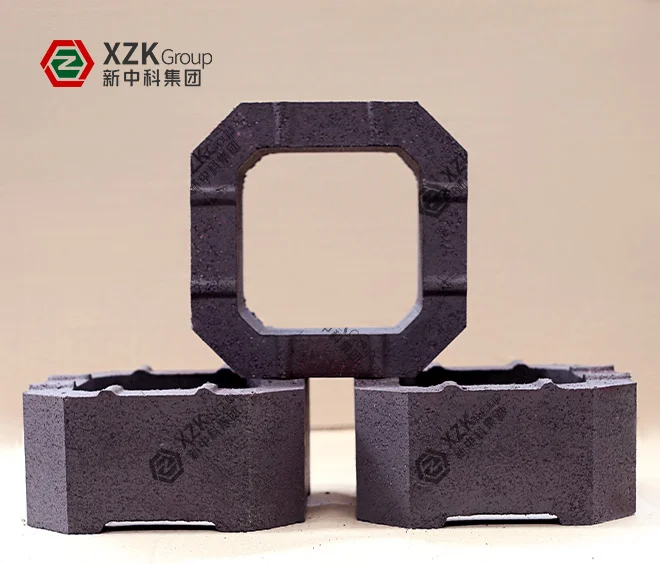

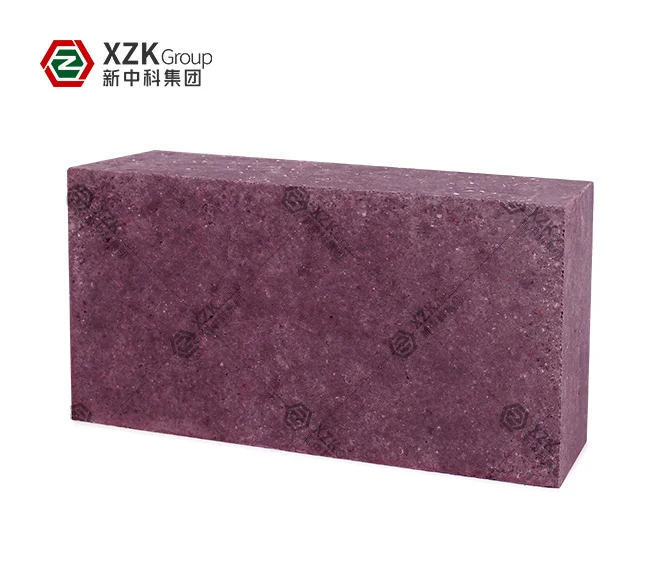

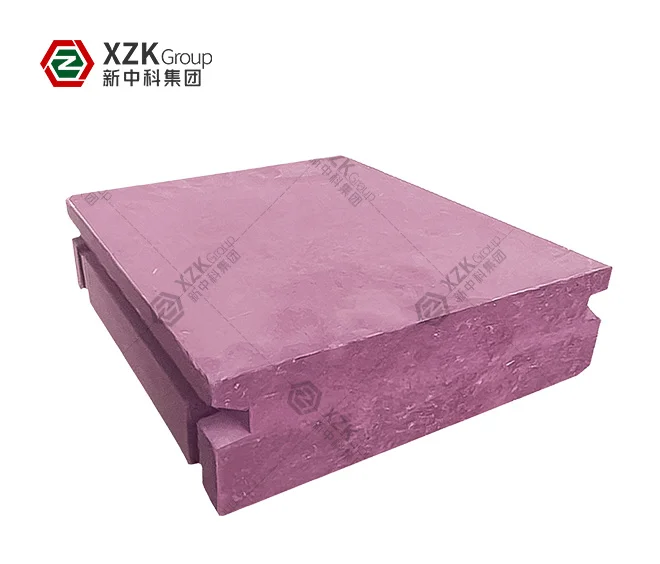

Cylindrical Chrome Corundum Brick

Chrome corundum octagonal brick: High - temperature stable, refractoriness 1770 - 2000°C. Resistant to erosion, alkali and sulfur. Used in regenerators of glass furnaces, metallurgy, energy chemical industry and environmental protection hazardous waste incinerators.

WhatsApp

WhatsApp

WeChat

WeChat

WhatsApp

WhatsApp

WeChat

WeChat